- Products

- Asphalt Plants – Continuous Mix

- Astec Double Barrel Green

DOUBLE BARREL GREEN

The benefits of warm mix asphalt such as reduced energy consumption, lowered emissions, and elimination of visible smoke are well-known in the hot mix industry. Warm mix technology allows mix to be prepared and placed at lower temperatures, typically 30°C to 60°C lower, than conventional hot mix. To achieve this, the viscosity of the bitumen must remain free flowing (low viscosity) at the reduced temperatures. Maintaining a low viscosity at lower temperatures allows mix to flow freely through storage, transfer and placement equipment and also is more easily worked by hand.

Previous technologies for warm mix production rely on additives, special bitumen, special procedures and/or special bitumen delivery systems to achieve low viscosities at low temperatures. The additives are expensive and add significant cost per ton of mix. The Double Barrel Green System eliminates the need for expensive additives and special bitumen by mixing a small amount of water and bitumen together to create microscopic bubbles. These small bubbles act to reduce the viscosity of the bitumen coating on the rock thereby allowing the mix to be handled and worked at lower temperature.

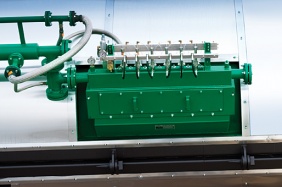

Water is injected via six water injectors into the liquid bitumen to produce foam. Bitumen flows through a series of six foaming chambers (one for each water injector) where water and bitumen are thoroughly mixed to produce the foamed bitumen necessary for WMA. Water is delivered to the system via a positive displacement piston pump capable of accurately metering water into the system. Water pump speed is modulated via feedback control to maintain the appropriate flow of water into the stand-pipe foaming chambers based upon the flow of bitumen. Six water injectors control the flow of water into each of six specially designed foaming chambers. PLC control provides for smooth and consistent operation of water injection as production rates increase or decrease. Water is provided to the system via

a skid-mounted corrosion-free water reservoir with an automatic filling valve that will keep the container full as long as water is supplied to it.

Key benefits of the Double Barrel Green System:

- 14% less fuel used in the virgin aggregate drying process

- 14% increase in production

- Ability to run high percentages of recycle mix with standard grade of asphalt

- Improved workability - The foamed liquid asphalt coating has a lower viscosity

- No smoke, no smell - The light oils in liquid asphalt never reach the boiling point, eliminating the smoke (vapour) and corresponding smell

- Longer pavement life - Due to less oxidation of mix and more uniformity of compaction

In addition to the benefits above, using a Double Barrel Green System contributes to a more comfortable, safe environment for workers, eliminates the need for fume systems on facilities and pavers, extends resources by using more recycle and does not increase production cost.

For more information about our range of products please call us on +44 (0)1440 821155 email us at sales@bgeuropa.co.uk or use our contact section.